Trigeneration (CHPC)

Trigeneration or combined

Heat Power and Chilling (CHPC)

Trigeneration, commonly referred to as Combined Heating, Cooling, and power (CHPC), is a clever approach to produce cooling, heating, and electricity while utilizing only one fuel source. Consider producing three different sources of energy all at once!

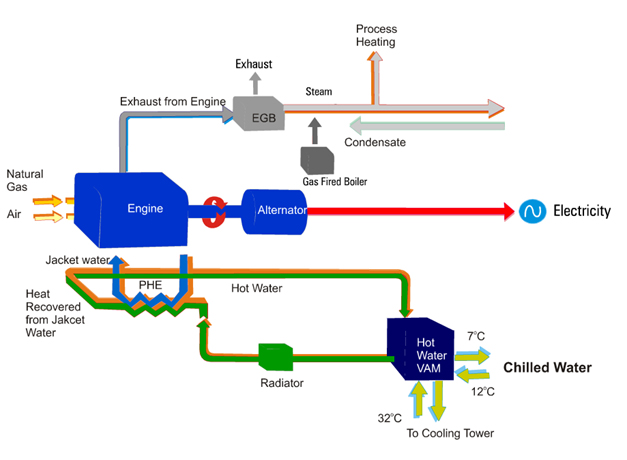

Trigeneration systems utilize power and cooling facilities to create energy, heat, and cooling simultaneously. With the use of cutting-edge technology, this innovative technique turns waste heat into chilled water. Following that, hot water and chilly air are produced using the leftover heat. It is like taking one action and getting three outcomes. Trigeneration refers to a cogeneration system that generates hot water & chilled water for air conditioning or process requirements.

The power component of CHPC systems is a gas generator. This section produces power, and a sophisticated mechanism also collects heat from the jacket water and exhaust waste heat. This waste heat is utilized in equipment like HWG to generate hot water, boiler for steam generation, or VAM for chilled water generation.

We’re excited to introduce you to the fascinating world of trigeneration. We’ll delve into topics like “Benefits of Trigeneration Application,” exploring its benefits. We will also focus on “Utilities Generated from Waste Heat,” highlighting the numerous energy forms it generates. We’ll also examine “Jacket Water Heat,” illuminating how it helps this creative process.

Join us on this journey of discovering the power of trigeneration with Green Power International, where we’re committed to eco-friendly gas gensets and advanced Gas engine generators.

Typical Diagram of Trigeneration Plant - Heat + Power + Chilled Water

Benefits of Trigeneration Application (CHPC)

Significantly Reduced Payback Period: Trigeneration integration in industrial settings offers a notably shorter payback period.

Buffer Against Electricity Cost Spikes: Gas-based trigeneration’s captive generation shields industries from sudden electricity cost surges. This independent energy source serves as reliable backup power, especially in critical scenarios like hospitals and commercial setups.

Sustainable Energy Independence: Utilizing natural gas replaces coal dependency and eliminates the need for extra energy for heat and cooling. Trigeneration systems can slash greenhouse gas emissions by up to 50%.

Enhanced Energy Efficiency: Trigeneration plants ensure up to 80% of primary energy reaches end-users, in contrast to just 30-35% in traditional power plants. On-site electricity production curbs transmission losses linked to grid-supplied electricity.

Eco-Friendly Cooling: Absorption chillers in trigeneration employ water or ammonia refrigerants, creating cooling systems with zero Ozone Depleting Potential and Global Warming Potential.

Utilities Generated from Waste Heat

- Steam for process application.

- Chilled Water: For Air-Conditioning and process requirements even at Sub-zero Temperature

- Hot Air: For Drying & Heating (generally used in ceramic industries, starch industries, etc.

- Hot Oil / Thermic Fluid: Heating & Drying Applications

- Hot Water: Industrial Use or Household uses in the kitchen or bathroom.

Discover the future of energy efficiency and sustainability through Green Power International’s pioneering trigeneration solutions. Trigeneration, or Combined Heating, Cooling, and Power (CHPC), redefines power generation by simultaneously producing cooling, heating, and power from a single fuel source. This innovative process offers reduced payback periods, insulation against electricity cost spikes, and enhanced energy independence. Waste heat is transformed into diverse utilities, including exhaust utilization, steam generation, chilled air-conditioning water, and sub-zero temperature applications. Our Jacket Water Heat systems provide chilled water for air conditioning, process cooling, and hot water for various industrial needs. At Green Power International, we are committed to delivering solutions that bridge energy efficiency and eco-consciousness. By embracing trigeneration, you’re not only enhancing your operational efficiency but also contributing to a more sustainable world.

Join us on this journey towards unparalleled energy efficiency and environmental stewardship. Let’s shape a greener and more sustainable future together.